Waste dewatering device (dryer)

Liquid sludge treatment refers to the processes applied to liquid sludge (fixation and dewatering). Sludge dryers are thermal drying systems designed to treat sludge in municipal wastewater treatment plants or industrial wastewater treatment plants. Sludge quality depends on the contaminants in the influent wastewater and the amount of suspended solids, which will have a major impact on the dry solids content and will determine the proposed equipment and equipment investment levels.

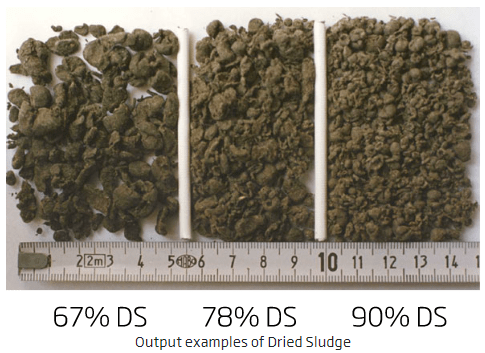

The purpose of providing this drying system is to reduce the volume of sludge/reduce the liquid content and increase the solid content of the sludge. Therefore, it significantly reduces disposal costs and enables reuse. The function of the dryer is that by pumping the sludge into the machine, the sludge spreads evenly against the external heating surface. The heating fluid (steam, water or thermal oil) flows outside the heating surface and the heat is transferred indirectly to the sludge film. The sludge is spread on the heated wall. The mixing blades move the sludge in a spiral path over the heated surface. Sludge retention time in the system is very short compared to other methods. As the sludge heats up, moisture is released and directed to the condenser. After a short time, the dried sludge, whose solid content varies from 30% to 90%, is transferred to the outside of the dryer and to the cooling coil if needed.

Due to the presence of important amounts of micronutrients such as iron, zinc, copper and manganese and macronutrients such as carbon, nitrogen and phosphorus, using the dry product obtained in the agricultural industry as a supplementary fertilizer can be considered as an option. Of course, the removal of dangerous compounds such as arsenic and the reduction of pollutant concentration must be managed. Otherwise, the dried product can be used for the renewable energy sector (common fuel for cement kilns, municipal waste incinerators), disposal in final waste sites, etc. By using this method, the volume of sludge and as a result the cost of moving, transporting and maintaining the final product is reduced.

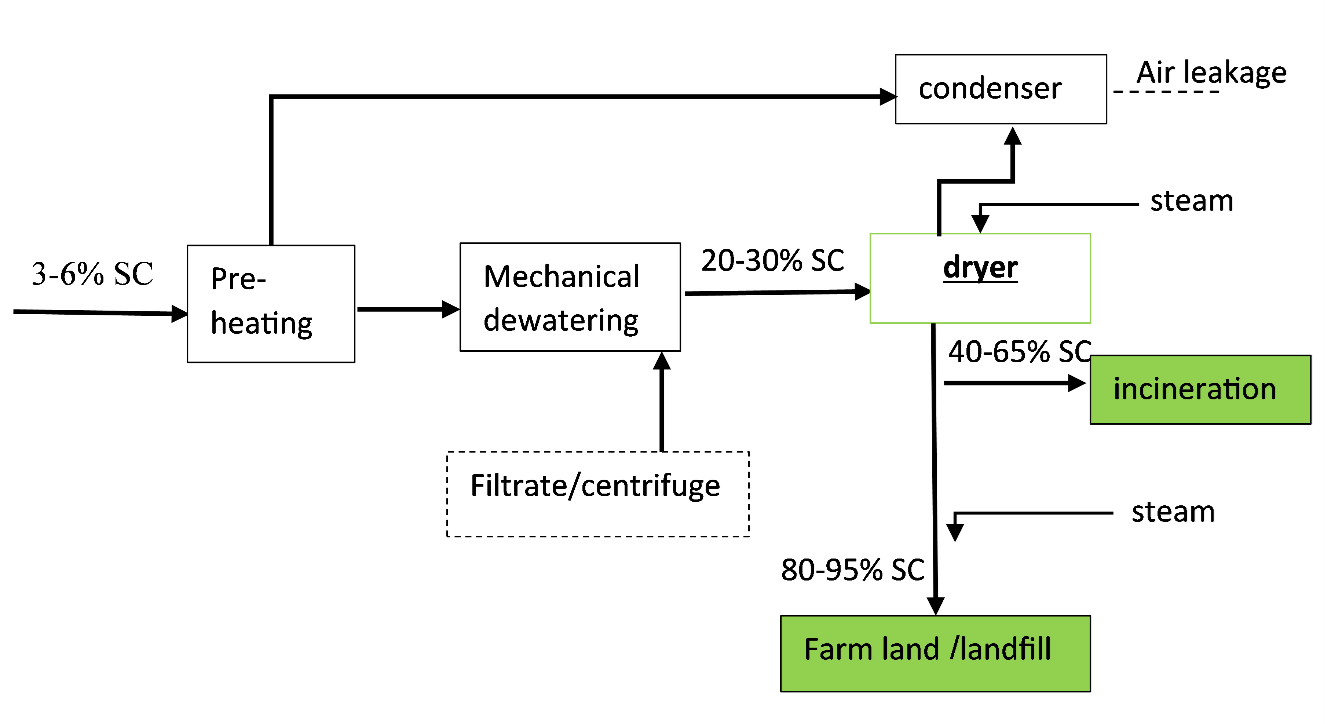

During the drying process, the incoming wastewater is converted into a dry product in several steps. In general, before using drying, sludge dewatering is done, which leads to reducing the initial moisture content of the product and reducing the costs of this process. Mechanical dewatering is usually done using filtration or centrifugation. The water in the sludge can be in the form of free water, absorbed water or intracellular water.

Two-stage operation diagram of sludge dryer

(use of twist dryer and vacuum dryer)

By combining two steps, the amount of solids obtained will be up to 95%. Before the sludge enters the vacuum dryer, it is dewatered by mechanical devices such as centrifuges, belt presses/filter presses. The solid content of sludge from these three different dewatering systems varies between 15 and 30 percent. Sludge dewatered by a centrifuge can pass through a preheater that is heated by process vapors from the thin film.